Spray systems

mobile

IGRALUB offers two different mobile spraying systems:

- Train Sys-AL, the airless spray system

- TOR Control

Airless spraying system

On-board system for top of rail friction management and wheel flange lubrication

The System

TrainSys-AL® is a system for lubricating the wheel flange and controlling friction between the rail crown and wheel tread without the use of a compressed air supply. The system is optimised for the use of HeadLub® friction modifier or RailLub® flange lubricant. The system consists of a storage tank, pumps, nozzles and a control unit. TrainSys-AL® has a modular design and can be adapted to the available installation space envelopes. A key design feature is accurate and consistent product application in all operating conditions.

Spray nozzle for top of rail friction management and/or flange lubrication

Control system

A commercially available control system (e.g. Siemens LOGO) can be used to define the spraying interval, pause times and the processing of the release signal or spraying commands from the vehicle control system. Test switches to allow manual spray activation can be incorporated.

Installation

The complete system is installed in the vehicle body adjacent to the bogie where the lubricant or friction modifier is to be applied. Metal pipes are used to connect the two pumps to the spray nozzles.

Special features

- Low maintenance system, no compressed air required

- Temperature-independent, constant product delivery rate

- Precise product application avoids wastage

- Pumps (left and right) can be controlled individually

- Designed for highly concentrated friction modifier containing solids (i.e. HeadLub® 90)

- Laboratory and operationally tested

- Customised tank configurations possible

TOR Control

IGRALUB Igralub AG, from Switzerland, has been involved in the subject of rail squeak on bends for more than 15 years, and, together with Railtec Systems GmbH, also from Switzerland, has brought a new develop- ment onto the market with the name of TOR Control (TOR). Unlike the earlier, simple systems for the detec- tion of curves (curve sensors, transponders, GPS), TOR Control is a computer that receives signals from GPS and other sources, and controls and triggers the spray commands on the basis of predefined criteria. This new system guarantees a predetermined and precise use. Operationally relevant inputs are also registered, and can be redefined in a manner specific to the pro- ject. These inputs are registered during the operation of the TOR computer, and are converted into the cor- responding commands. The use of lubricants on the railhead can thereby be controlled.

The following components are thereby used:

Lubrication system

The application of the lubricant takes place by means of a spray system built into the vehicle, which, while travelling, sprays a specific amount of the lubricant onto the railhead during a predefined spray period by means of compressed air (at 6-8 bar). This spray com- mand is carried out by one or more solenoid valves in the system. The spray quantity and the spray dura- tion are determined in advance. In the case of longer curves, the spray intervals are repeated until the end of the curve. If there is no compressed air available in the vehicle, a corresponding compressor unit will also have to be installed. In certain vehicle models, the installation of the compressor unit takes place in the bogie or in the interior area of the vehicle. All the signals available from the spraying system and the compressor unit are registered by the TOR Control, and can be used for monitoring and control.

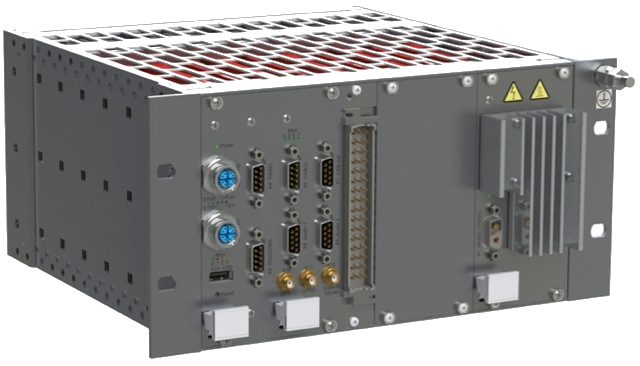

Controller

Igralub has developed a controller that is sold under the name “TOR Control”. This is a computer whose software is linked to incoming operational signals and that provides the correspon- ding commands from them. Many of these operatio- nal signals are already available in most vehicles and can be very easily accessed by the system. Various interfaces are available for this: LAN, CAN, digital I/O, analog inputs, frequency inputs and serial ports.

Precise spraying

The TOR Control detects the precise application locations by means of GPS, the vehicle speed and any other available signals. This takes place in both the open air and in tunnels. In the case of a loss of signals, the distance to the defined spray location is calculated from the vehicle speed. The definitions of the precise spraying locations and their length are achieved from a mapping that is directly created during a teach-in run using a laptop in the vehicle. The setting of the spray command takes place using a simple software that is a component part of the supplied operatio- nal software. The exact positions can be entered into the route plan created from the mapping by simply setting the start and end points. Modifications or the addition of new spray locations are possible at any time and can be carried out by the operator himself. This intervention into the operational software is simple, and requires no programming know-how.

Manual control for mobile spraying systems

Manual control

It is possible to trigger the command to spray the rail head manually via a button in the driver’s cab. However, this method is highly dependent on people and requires a high level of discipline. This device is mainly recommended for small and mountain railways.

The manual release

The command to spray the rail head is given manually via a button installed in the driver’s cab. With this button 1 to 3 cycles per spraying pulse can be set, inside or outside rail.

Along the track, a spray signal display board is installed at the points where spraying is to take place. The HL sign shows the driver where to start the application. (if no GPS signal or transponder is used).

Spray signal display panel

Several hand controls